Flexible vs. Rigid Packaging: What Food Manufacturers Need to Know

If you’re a food manufacturer, you know packaging isn’t just something you place a product in, it’s part of the product itself. And the decision between flexible and rigid packaging can impact everything from self-life to sustainability goals to shipping costs. This is a conversation we have a lot with brands we work with, especially those looking to improve quality or meet evolving sustainability expectations. So, here’s a straightforward look at the differences, and where flexible packaging might make sense for you.

What Do We Mean by “Flexible Packaging”?

Flexible packaging includes pouches, roll stock, laminated bags, lidding film, anything that bends, conforms, or forms around your product. We make a wide range of these at

Portco, including:

Roll stock for form-fill-seal equipment

Stand-up pouches for frozen and dry goods

Multiwall bags for ag, grain, and other bulk products

Tray and container lidding

And sustainable structures through our EarthGuard™ line

Flexible packaging gives you options, high-barrier, sustainable, lightweight, and often more cost-effective to ship and store.

What About Rigid Packaging?

Rigid packaging includes things like:

Glass jars

Plastic tubs or bottles

Aluminum cans

It’s typically heavier, takes up more space, and often requires secondary packaging. It has its place — especially for liquids and items that need crush-proof strength — but there are tradeoffs.

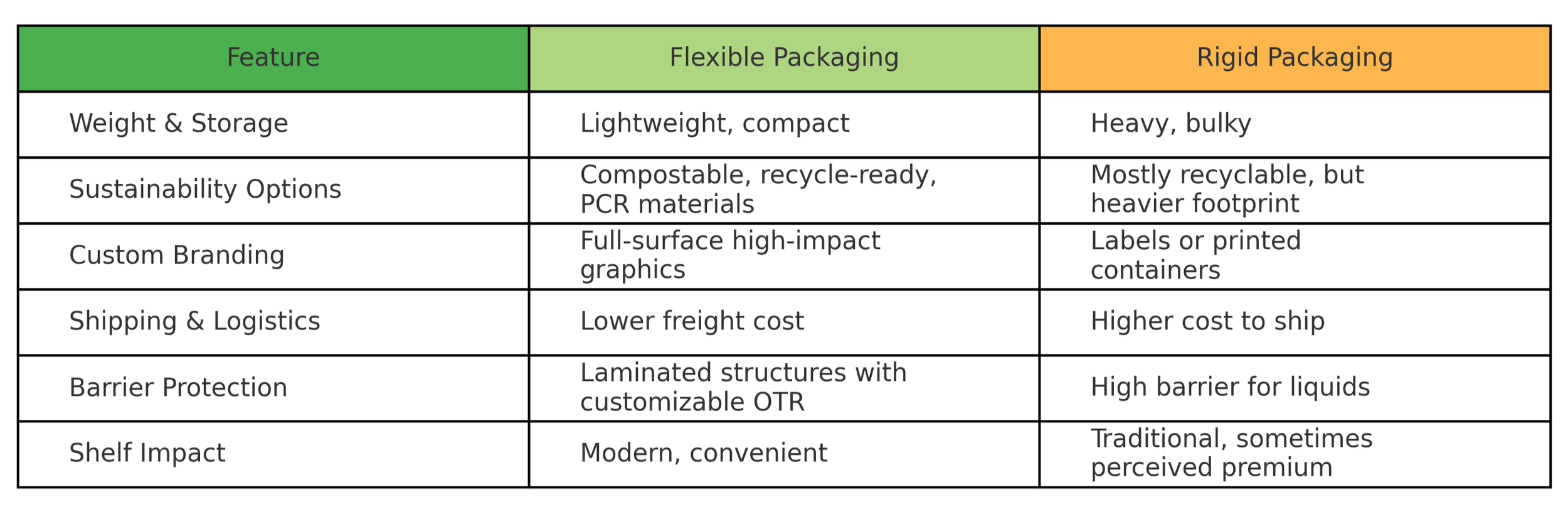

Quick Comparison

Why More Brands Are Moving to Flexible

We’re seeing a clear shift. Especially among brands in frozen, dry, and prepared food categories — flexible packaging is helping them:

Reduce packaging weight

Improve pallet efficiency

Lower transportation costs

Hit sustainability targets

Customize barrier properties for shelf life

Improve consumer convenience (zipper closures, resealable, etc.)

It’s not about following a trend. It’s about building a packaging format that makes sense for your product, your line, and your goals.

Let’s Talk EarthGuard™

If sustainability is part of your brand’s mission, or your retail customers are asking for it, you’ll want to check out our EarthGuard™ platform. EarthGuard gives you flexible packaging options that meet performance and food safety standards while also hitting sustainability benchmarks. We offer:

Compostable films and laminates

Recycle-ready mono-material solutions

Post-consumer recycled (PCR) content options

Each is engineered to meet the specs you need without compromising shelf life or production efficiency.

So… Which Should You Choose?

If your product needs:

High performance

Food safety

Extended shelf life

Lower cost per unit shipped

A path toward sustainability

…flexible packaging may be worth a closer look.

Rigid still has its place, but for many of our customers, switching to flexible has created real operational and brand-level wins.

We’re Here to Help

At Portco, we don’t just print and convert it. We help you find the packaging format that’s right for where your business is going next. If you’re considering a change or just want to know what options are out there, let’s talk.